No products

Prices are tax included

audiohobby

Coils

- Lundahl transformers

- Lundahl Tube output

- Lundahl Moving coil input

- Lundahl Input and DC-free line output application

- Lundahl Anode chokes, interstage and line output

- Lundahl Mains transformers

- Lundahl Chokes for tube amp power supply or filament current supply

- Lundahl General purpose

- Lundahl Microphone transformers

- Lundahl Line input

- Lundahl Line output transformers

- Lundahl Problem solvers

- Lundahl Digital Audio

- Lundahl Transformers for telephone hybrids, for 100V PA systems

- Lundahl Video transformers

- Lundahl Metal Housings

- Lundahl Amorphous core output transformers

- Lundahl other audiophile type transformers

- Capacitors

- Mundorf ECap

- Mundorf MCap

- Mundorf MCap RXF

- Mundorf MCap ZN

- Mundorf MCap SUPREME

- Mundorf MEAI

- Mundorf MEAIO

- Mundorf MESGO

- Mundorf MCap SUPREME silver/oil

- Mundorf MCap SUPREME silver/gold

- Mundorf MCap SUPREME silver/gold/oil

- Mundorf TubeCap

- Mundorf MLytic HV

- Mundorf MLytic AG

- Mundorf MLytyc HC

- Auricap XO

- Jantzen Audio MKT Cap

- Jantzen Audio Cross Cap

- Jantzen Audio Standard Z-Cap

- Jantzen Audio Superior Z-Cap

- Jantzen Audio Silver Z-Cap

- Jantzen Audio Copper Foil Amber Z-Cap

- Jantzen Audio Alumen Z-Cap

- Jantzen Audio SilverGold Z-cap

- Rike Audio S-cap Paper in Oil

- Mundorf Mlytic HC+ (4-pole)

- Mundorf MLytiv HV+ (4-Pin High Voltage Power Cap)

- Mundorf MCap SUPREME EVO

- Mundorf MCap SUPREME EVO Oil

- Mundorf MCap SUPREME EVO SilverGold

- Mundorf MCap SUPREME EVO SilverGold Oil

- Mundorf MLytic AG+

- RIKE Audio Q-Cap Copper Oil Polypropylen Capacitors

- RIKE Audio Oil-Paper-Capacitors - S-Cap 2

- Rike Audio Q-CAP2 PIO Copper Paper Oil capacitors

- Miflex Audio Capacitors

- Coils

- Mundorf M-Coil

- Mundorf M-Coil BV

- Mundorf M-Coil VL

- Mundorf MCoil VNCU ZeroOhm (resin-soaked)

- Mundorf M-Coil LL Hepta Strand

- Mundorf M-Coil CF

- Mundorf M-Coil transformer-core

- Mundorf M-Coil CF transformer-core

- Mundorf M-Coil BV transformer-core

- MCoil VT transformer-core vacuum impregnated

- Mundorf M-Coil CF i-core

- Mundorf M-Coil BV i-core

- Mundorf M-Coil drum-core

- Mundorf M-Coil drum-core BV

- Mundorf M-Coil pin-core

- Mundorf M-Coil rod-core

- Mundorf M-Coil BV rod-core

- Mundorf M-Coil CF rod-core

- Mundorf M-Coil zero-ohm

- Mundorf M-Coil CF silver

- Mundorf M-Coil silver/gold

- Jantzen Air Cored Wire Coil

- Jantzen 13AWG 1,8mm Air Core Coils

- Jantzen 14AWG 1,6mm Air Core Coils

- Jantzen 15AWG 1,4mm Air Core Coils

- Jantzen 17AWG 1,2mm Air Core Coils

- Jantzen 18AWG 1,0mm Air Core Coils

- Jantzen 20AWG 0,8mm Air Core Coils

- Jantzen 21AWG 0,7mm Air Core Coils

- Jantzen 22AWG 0,63mm Air Core Coils

- Jantzen 24AWG 0,5mm Air Core Coils

- Jantzen 26AWG 0,4mm Air Core Coils

- Jantzen 29AWG 0,3mm Air Core Coils

- Jantzen Audio Wax Coil

- Jantzen Iron Cored Coils With Discs

- Jantzen 13AWG 1,8mm Iron Cored Coils with Discs

- Jantzen 14AWG 1,6mm Iron Cored Coils with Discs

- Jantzen 15AWG 1,4mm Iron Cored Coils with Discs

- Jantzen 17AWG 1,2mm Iron Cored Coils with Discs

- Jantzen 18AWG 1mm Iron Cored Coils with Discs

- Jantzen 20AWG 0,8mm Iron Cored Coils with Discs

- Jantzen 21AWG 0,7mm Iron Cored Coils with Discs

- Jantzen 22AWG 0,63mm Iron Cored Coils with Discs

- Jantzen 24AWG 0,5mm Iron Cored Coils with Discs

- Jantzen 26AWG 0,4mm Iron Cored Coils with Discs

- Jantzen 29AWG 0,3mm Iron Cored Coils with Discs

- Jantzen C-Coil - Toroidal Core

- Jantzen Audio Cross Coil

- Jantzen Audio Iron Coil

- Jantzen Audio Iron Coil 13AWG

- Jantzen Audio Iron Coil 14AWG

- Jantzen Audio Iron Coil 15AWG

- Jantzen Audio Iron Coil 17AWG

- Jantzen Audio Iron Coil 18AWG

- Jantzen Audio Iron Coil 20AWG

- Jantzen Audio Iron Coil 21AWG

- Jantzen Audio Iron Coil 22AWG

- Jantzen Audio Iron Coil 24AWG

- Jantzen Audio Iron Coil 26AWG

- Jantzen Audio Iron Coil 29AWG

- Jantzen Audio Litz Wire Wax Coil

- Mundorf MCoil VLCU

- Mundorf MCoil VSCU

- Mundorf MCoil VS iCore (resin-soaked)

- Parts for x-over assembling

- Resistors

- Solder

- Wires, plugs, terminals and more

- Interconnect Cable

- Speaker Cable

- Power Cable

- Phono & Tonarm cables

- Hook up Wire

- DH-Labs connectors

- WBT Connectors

- Mundorf M-Connect LS plugs

- Mundorf M-Connect terminals

- Mundorf M-Connect CF

- Mundorf M-Connect silver/gold SGW

- Mundorf M-Connect NF Plugs

- Jantzen Speaker Terminals

- Jantzen Port Tubes

- Damping Materials

- Waveguides and adapters

- Speaker Spikes

- Jantzen audio cables

- Wattgate Power Connectors

- Speaker grill cloth

- Headphone cable and connectors

- Heatshrinks, braided sleves for DIY cable

- Speaker jumpers and terminal bridges

- Speaker building accessories

- Kimber Kable

- Furutech

- ETI Research connectors

- Oyaide

- RCA Sockets

- AudioQuest

- AudioQuest DAC

- AudioQuest USB Extenders and Adaptors

- AudioQuest Power Cables

- AudioQuest Power Conditioners

- AudioQuest Accessories

- AudioQuest Speaker Cables

- AudioQuest Audio Interconnect Cables

- AudioQuest Subwoofer Cables

- AudioQuest Tonearm Cables

- AudioQuest Turntable Cables

- AudioQuest Vinyl and Headphone Accessories

- AudioQuest HDMI Cables

- AudioQuest USB Cables

- AudioQuest Optical Cables

- AudioQuest Digital Coax Cables

- AudioQuest AES/EBU (Balanced) Cables

- AudioQuest Ethernet Cables (RJ/E)

- AudioQuest SureGrip® Speaker Connectors

- AudioQuest CL3/FT4 In-Wall Rated Bulk Audio Interconnect Cables & Plugs

- AudioQuest Spade, Pin, and Banana Connectors

- AudioQuest Instant Tool-less Connectors (ITC) for Analog-Audio, Mini-Coax, and RG6 Cables on Spools

- AudioQuest CL3/FT4 In-Wall Rated Bulk Speaker Cables

- AudioQuest Bulk Speaker Cables — Not In-Wall Rated

- AudioQuest CL3/FT4 In-Wall Rated Bulk CAT6 and CAT7 Ethernet Cables & Plugs

- Nordost

- Nordost power cords

- Nordost analog Interconnects

- Nordost subwoofer cables

- Nordost iKables

- Nordost BLUE HEAVEN headphone cables

- Nordost Ethernet-HDMI-4K-USB

- Nordost digital Interconnects

- Nordost tonearm cables

- Nordost speaker cables

- Nordost QRT – Audio Enhancers

- Nordost Sort Systems – Resonance Control

- Nordost Bulk-Specialty

- Nordost Accessories-Apparel

- Audience AV

- Power supply cables/accessories

- Kits, DIY and Loudspeaker upgrade kits

- Speaker Drivers

- Tweeters

- Midrange Drivers

- Fullrange

- Coaxial Drivers

- Midwoofer Drivers

- Woofers

- Passive Radiators

- Subwoofers

- Car Audio drivers

- Scan-Speak Discovery

- Scan-Speak Classic

- Scan-Speak Revelator

- Scan-Speak Illuminator

- Seas Prestige

- Seas Excel

- Seas Exotic

- Seas Lotus

- Design by SEAS

- SB Acoustics

- SB Acoustics Tweeters

- SB Acoustics Midrange

- SB Acoustics Midwoofer

- SB Acoustics Woofers

- SB Acoustics Passive radiators

- SB Acoustics Subwoofer

- SB Acoustics Satori

- Accuton

- Audiotechnology

- Mundorf Hi-Fi AMT U Series tweeters

- Speaker driver accessories

- Monitor Audio

- Loudspeakers

- Metrum Acoustics DACs

- Soldering and termination services

- Soundcare spikes

- Hi-Fi and Hi-End equipment

- Mediaplayers

- Amplifiers

- Speakers

- Vinyl Players

- Earthequake Sound Home Audio

- Earthequake Sound Car Audio

- Earthequake Sound Gaming Audio

- Earthequake Sound Pro Audio

- Sonnet digital audio

- Power conditioners and distributers

- Streamers

- Portable headphone amplifiers

- Fuses and fuse holders

- Headphone Amplifiers

- DACs

- CD/SACD-players

- Turntables

- Tonearms

- Accessories

- Plate amplifiers, modules, power supplies

- DIY Amplifier modules

- DSP devices

- Services

- Accuton

- Analog Manufaktur Germany

- Anthem

- Audes

- Audience

- Audiobyte

- AudioQuest

- AudioTechnology

- Bliesma Audio

- Bluesound

- Bryston

- Clearaudio

- DALI

- Dayton Audio

- Denon

- DH-Labs

- Duelund Audio

- Dune HD

- Dynaudio

- Earthquake Sound

- ELAC

- Electrocompaniet

- ETI Research

- Eversolo

- Feickert Analogue

- Ferrum Audio

- Fountek

- Furutech

- Hegel

- Hi-Fi Tuning

- HiVi

- Hypex electronics

- IsoAcoustics

- Jantzen Audio

- Kimber Kable

CoilsThere are 5696 products.

Subcategories

Mundorf M-Coil

MCoil Air Coils made from massive copper round-wire have been specially developed for high quality loudspeakers, which focus on achieving an utmost natural, detailed and acoustically balanced music performance. The acoustical properties of the L series can yet be significantly enhanced by applying Baked Wire Treatment - on air coils using wires with a larger cross-section - by Vacuum Impregnation. Baked Wire Treatment coils are listed as BL in the following table. Vacuum impregnated coils are marked VL. Technical specifications: OFC-Copper 99.99% Coil form: PA, fibre-glass reinforced Coil body heat resistant up to max. 230°C/446°F

Mundorf M-Coil BV

Mundorf M-Coil VL

MCoil Air Coils made from massive copper round-wire have been specially developed for high quality loudspeakers, which focus on achieving an utmost natural, detailed and acoustically balanced music performance. The acoustical properties of the L series can yet be significantly enhanced by applying Baked Wire Treatment - on air coils using wires with a larger cross-section - by Vacuum Impregnation. Baked Wire Treatment coils are listed as BL in the following table. Vacuum impregnated coils are marked VL. Technical specifications: OFC-Copper 99.99% Coil form: PA, fibre-glass reinforced Coil body heat resistant up to max. 230°C/446°F

Mundorf MCoil VNCU ZeroOhm...

Mundorf MCoil VNCU ZeroOhm (resin-soaked)

Mundorf M-Coil LL Hepta Strand

MCoil Hepta Strand coils unite the tonal clarity. beauty and distortion-free performance of air core coils with the stereophonic spaciousness of tightly-wound coils. alongside the harmonious-warmth and splendid brightness of strand copper wire.

They are therefore the first choice for high quality high and mid frequency applications which focus on a finely detailed. utmost refined musical fidelity performed within a truly holographic life-like staging.Mundorf M-Coil CF

Mundorf M-Coil transformer-core

Mundorf M-Coil CF transformer-core

Mundorf M-Coil BV transformer-core

MCoil VT transformer-core vacuum...

Mundorf M-Coil CF i-core

Mundorf M-Coil BV i-core

Mundorf M-Coil drum-core

FERRIT Core Coils

MCoil Drum core

MCoil Drum-Core coils made from oxygenfree copper (OFC) round-wire have been developed for mid, low and parallel applications for which compact dimensions, a low basic distortion level as well as the lowest possible internal resistance and a reasonable value for money ratio are of key importance.

The tonal quality of these coils is a convincing blend of the typical harmoniously-neutral sound of solid core copper round-wire and the natural vitality and enhanced tonal dynamic of HP3616.

The fine properties of the H series can be further improved by applying Baked Wire Treatment as introduced with BH series.

Specifications:

Core material: HP 3616

OFC-Copper 99.997%Mundorf M-Coil drum-core BV

FERRIT Core Coils

MCoil Drum core

MCoil Drum-Core coils made from oxygenfree copper (OFC) round-wire have been developed for mid, low and parallel applications for which compact dimensions, a low basic distortion level as well as the lowest possible internal resistance and a reasonable value for money ratio are of key importance.

The tonal quality of these coils is a convincing blend of the typical harmoniously-neutral sound of solid core copper round-wire and the natural vitality and enhanced tonal dynamic of HP3616.

The fine properties of the H series can be further improved by applying Baked Wire Treatment as introduced with BH series.

Specifications:

Core material: HP 3616

OFC-Copper 99.997%Mundorf M-Coil pin-core

Mundorf M-Coil rod-core

ARONIT Core coils

MCoil Rod core coils

Aronit cores (also known as P cores) consist of high-density metal-ceramics-powder. The German- made Wicon ferrite rods produce extremely low distortion, even at very high loadings. Due to their highly compact dimensions, their low internal resistance and their excellent price/performance ratio they are particularly suitable as bass and subwoofer coils and for PA applications.

MCoil Rod core coils combine the balanced, detailed and dynamic tone colour of OFC round wire with the low output distortions and internal resistance of Aronit cores. They are therefore an excellent choice for good value and compact yet high-capacity middle-low and low frequency coils, including for PA applications. The great features of line A as well as the transparent and undistorted music reproduction can be enhanced even further in line BA by using self-bonding wire.

Technical specifications:

Core material: ARONIT

OFC-Copper 99.99%

Coil form: PA, fibre-glass reinforced

Coil body heat resistant up to max. 230°C/446°FMundorf M-Coil BV rod-core

Mundorf M-Coil CF rod-core

Mundorf M-Coil zero-ohm

Mundorf M-Coil CF silver

Mundorf M-Coil silver/gold

Jantzen Air Cored Wire Coil

High-purity copper wire baked in perfect shape to create a distortion-free inductor, for all audio applications.

Modern self-supporting design, low tolerance (+/-3%) and power handling dependent on the wire used, makes it the most versatile coil on the market.

Description: Enamellled copper wire solderable with self-bonding topcoat, class 155, acc to IEC 60317-35, DIN EN 60317-3Production range: Grade 1B 0.30 0.40 0.50 0.63 0.70 0.80 1.00 1.20 1.40 1.60 1.80 mmInsulation: Polyurethane with aliphatic polyamide bondcoatFeatures: Temperature index of 155, solderability at 390°C without removing the enamel coating, bonded under action of heatApplications: Used for self supporting coils, windings for deflection yokes, watchmaking, loudspeaker coils, small motorsTypical values for FLS 155 dia 1,00 mm Grade 1B, testing according to IEC 60851.1...6Mechanical properties:Flexibility: 10% 1 dElongation: ³30 %Thermal properties:Temperature index: 155Cut through: ³ 200°CHeat shock at 175°C: 1xdBonding temperature: 170-200°CResoftening temperature: 155°CElectrical properties:Breakdown voltage: > 1,5 IECTangent delta /TD 300/: ³ 140Chemical properties:Solderability at 390°C: 8 sJantzen Audio Wax Coil

This product has been revived through cooperation with our audio partners.

The insulation used for Wax Coils is a special 60 μm quality paper. The coil is wound with the same 99,99% pure copper foil, also used for Cross Coils. Each coil is impregnated with a polymolecular paraffin Wax, making the coil hard as a rock! Each coil is tested with Clio system.

Tolerance +/-2%

Wax Coils are available in the following sizes:

16AWG - 1,33 mm2 , coil height 24 mm

14 AWG - 2.10 mm2, coil height 36 mm

12 AWG - 3,29 mm2, coil height 54 mm

8 AWG – 8,46mm, coil height 54mm

Wax Coil 16 AWG sustains 350 Watts RMS

Wax Coil 14 AWG sustains 500 Watts RMS

Wax Coil 12 AWG sustains 650 Watts RMSJantzen Iron Cored Coils With Discs

High-purity copper wire wound around a Permite core (or core + discs), for a high inductance at the lowest cost.

Extremely low DCR which does not alter driver damping factor and loss of efficiency.

The Permite material provides significant lower hysteresis compared to coils with ferrite cores, at the same time delivering higher power handling than the ferrite ones.

Recommended for bass section only.

Power handling 400 watts RMS.

About baked wire used for Jantzen Induction coils:

Description: Enamellled copper wire solderable with self-bonding topcoat, class 155, acc to IEC 60317-35, DIN EN 60317-3Production range: Grade 1B 0.30 0.40 0.50 0.63 0.70 0.80 1.00 1.20 1.40 1.60 1.80 mmInsulation: Polyurethane with aliphatic polyamide bondcoatFeatures: Temperature index of 155, solderability at 390°C without removing the enamel coating, bonded under action of heatApplications: Used for self supporting coils, windings for deflection yokes, watchmaking, loudspeaker coils, small motorsTypical values for FLS 155 dia 1,00 mm Grade 1B, testing according to IEC 60851.1...6Mechanical properties:Flexibility: 10% 1 dElongation: ³30 %Thermal properties:Temperature index: 155Cut through: ³ 200°CHeat shock at 175°C: 1xdBonding temperature: 170-200°CResoftening temperature: 155°CElectrical properties:Breakdown voltage: > 1,5 IECTangent delta /TD 300/: ³ 140Chemical properties:Solderability at 390°C: 8 sJantzen C-Coil - Toroidal Core

C-Coil is wound around a sandwich core, and it has extremely low resistance and can shift a large amount of power without getting over heated.

The core is formed like a donut with a round cross section, and it is wound from one long piece of laminated steel tape.

The surface of the core is epoxy coated to secure against short circuit even at a very high load.We have tested the inductor with a carrying load of 1000 Watt, and it lasted and stood up well.

It can stand upto 700 Watt per 48 hrs in one go.We are very satisfied with the result.

The C-Coil is designed for Bass, Sub-Woofer and Amplifiers, in different core and wire sizes.Please note!

The C-Coil cannot be measured using a universal LC meter. Due to the characteristics of the core and winding method, it is important to use a professional RLC meter. We measure all C-Coils before shipping them using a professional RCL meter at AC 1 V 1 kHz.

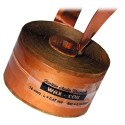

Jantzen Audio Cross Coil

The Cross Coil has been developed in cooperation with Audio Technology, Denmark, producing high-end drivers for the world market.

No chain is stronger than its weakest link. This is especially so when we speak of loudspeakers, where there is often a cost reduction for crossover inductors. The result is distortion and power loss.

High-end loudspeaker producers overcome this problem by using foil coils, where the copper is flat instead of round.

Cross Coils are available in 12, 14 and 16 AWG.

On special request we can also offer Cross Coils in 8 AWG

Jantzen Audio Iron Coil

High-purity copper wire wound around a Permite core, for a high inductance at the lowest cost.

Extremely low DCR which does not alter driver damping factor and loss of efficiency.

The Permite material provides significant lower hysteresis compared to coils with ferrite cores, at the same time delivering higher power handling than the ferrite ones.

Recommended for bass section only.

Power handling 400 watts RMS.

Sorted by mH

Jantzen Audio Litz Wire Wax Coil

Jantzen Audio Litz Wire Wax Coil

The Litz Wire Wax Coil offers reduced skin effect and lowered resistance, compared to conventional wire based inductors, which in turn offers more dynamic head room and clearer sound.

We have impregnated our Litz Wire Coils in the same high quality wax used for the Wax Coil.

Making the Litz Wire Coils wax impregnated offers a much firmer coil and secures the windings in place (eliminating microphonic effect).

Mundorf MCoil VLCU

MCoil VLCU Paper Copper Film Inductors. Ultra-soft Abacá Esparto special paper as a dielectric medium dip-impregnated with viscoplastic insulation resin.

High mechanical damping of the coil-vibrations. Almost free of microphonic effect, even without a housing. Extremely calm acoustic pattern and the finest micro-dynamics.Mundorf MCoil VSCU

Copper Foil Paper

Mundorf MCoil VS iCore (resin-soaked)

Mundorf MCoil iCore (resin-soaked)

Mundorf M-Coil VSCU 0,12 mH 15 AWG 1,40mm...

Inductivity 0,12 mH

39,15 €In Stock

32,09 € tax excl.***Mundorf M-Coil VSCU12 1,2mH 12AWG 1,98mm...

Inductivity 1,2 mH

76,16 €In Stock

62,43 € tax excl.***Coil Mundorf M-Coil 0,81mm,² · AWG 18 |...

CFC18-0,12 0,81mm² · AWG 18 | 1,02mm (baked)

14,14 €In Stock

11,59 € tax excl.***Coil Mundorf MCoil iCore 7,00mm² · AWG 9 |...

VSCU9-1,2 7,00mm² · AWG 9 | 2,99mm (resin-soaked)

132,07 €In Stock

108,25 € tax excl.***Coil Mundorf MCoil iCore 0,79mm² · AWG 18...

VS100-5,6 0,79mm² · AWG 18 | 1,00mm (resin-soaked)

40,57 €In Stock

33,25 € tax excl.***Coil Mundorf MCoil iCore 1,23mm² · AWG 16...

VS125-3,9 1,23mm² · AWG 16 | 1,25mm (resin-soaked

46,67 €In Stock

38,25 € tax excl.***Coil Mundorf MCoil 1,54mm² · AWG 15 |...

VS140-1,5 1,54mm² · AWG 15 | 1,40mm (resin-soaked)

40,57 €In Stock

33,25 € tax excl.***Coil Mundorf MCoil 2,55mm² · AWG 13 |...

VS180-1,2 2,55mm² · AWG 13 | 1,80mm (resin-soaked)

50,74 €In Stock

41,59 € tax excl.***Coil Mundorf MCoil ZeroOhm 1,23mm² · AWG...

VN125-18 1,23mm² · AWG 16 | 1,25mm (resin-soaked)

116,82 €In Stock

95,75 € tax excl.***

-

Wavecor silk dome tweeter TW030WA05, 4 Ohm

56,61 € -20% 70,76 €

46,40 € tax excl.***