Soundcare superspikes 1101 self-adhesive Titanium, pack of 3pcs

Soundcare superspikes 1101 self-adhesive Titanium, pack of 3pcs

Soundcare® SuperSpike TITANIUM models: For the TITANIUM SuperSpikes only the best materials have been chosen to make the most exclusive spike on the market. The TITANIUM Super Spikes are made for people that want the best.

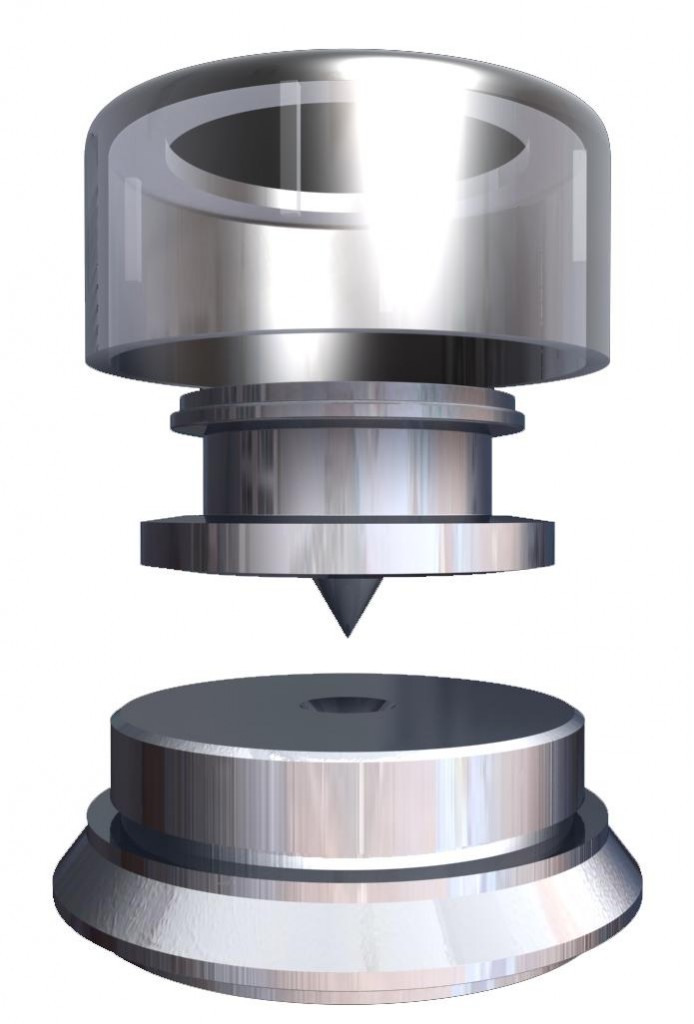

All parts are produced with very small tolerances. This, in addition to using TITANIUM grade 5 in the spike (a very difficult alloy to make) and TITANIUM grade 2 (pure TITANIUM) for the based plate, all integrated in a polycarbonate housing, makes the ultimate spike for the most exclusive equipments.

How it is designed

All Soundcare® spikes are spikes with a rounded tip (0,5 mm in diameter) standing in a crater with

a flat bottom. In this way we get a very small contact area combined with enormous strength.

Load tolerances is only of theoretical interests. For standard spikes you can put 400 kg per spike,

for the TITANIUM models even more.

The Soundcare TITANIUM SuperSpike is an assembly of :

Spike made of TITANIUM grade 5 (extremely hard alloy made for the space industry).

Protection disc made of TITANIUM grade 2 (pure TITANIUM).

Polycarbonate housing

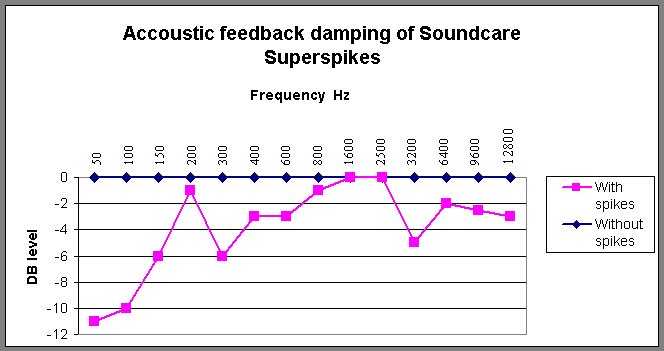

The Measurement

Measurements for Soundcare SuperSpikes:

A calibrated loudspeaker has been fed with a sinus wave on each frequency level. The loudspeaker has been placed upon a calibrated pressure sensitive microphone. For each frequency the signal is fed through the loudspeaker and the output level is adjusted to specific level which is referred to as 0 dB. Then the spike is placed between the loudspeaker cabinet and the pressure sensitive microphone. The same signal with the same output level is used. The level from the microphone is then measured. The direct sound through air from the loudspeaker to the microphone is never measured louder than –30 dB for any of the frequencies. The curves will therefore show the approximate transmission of energy from loudspeaker cabinet through the spike and down to the microphone.

In words the damping of acoustic feedback is:

We do not know of any other that has measured spikes this way before. Until now spikes only have been listening tested as far as we know. This is a way to try to measure the benefits in a way that makes it possible to show the results on paper. There can be inaccuracy because of unknown resonances and other unknown influence, but we are sure these results show how spikes reduce acoustic feedback.

The influence of reducing the feedback at one frequency for another is not measured. Listening tests show that reducing feedback at low frequencies does have large influence on the sound quality at higher frequencies. The different models, threaded and self-adhesive have been tested. The results are so similar for the different models that it does not influence the curve. At 50Hz (the most important frequency to damp) we had a reduction of 11 dB, which means that appr. 95% of the feedback energy was stopped.

Не удаётся отправить вашу оценку отзыва

Пожаловаться на комментарий

Жалоба отправлена

Не удаётся отправить вашу жалобу

Оставьте свой отзыв

Отзыв отправлен

Не удаётся отправить отзыв

Soundcare superspikes 1101 self-adhesive Titanium, pack of 3pcs

check_circle

check_circle